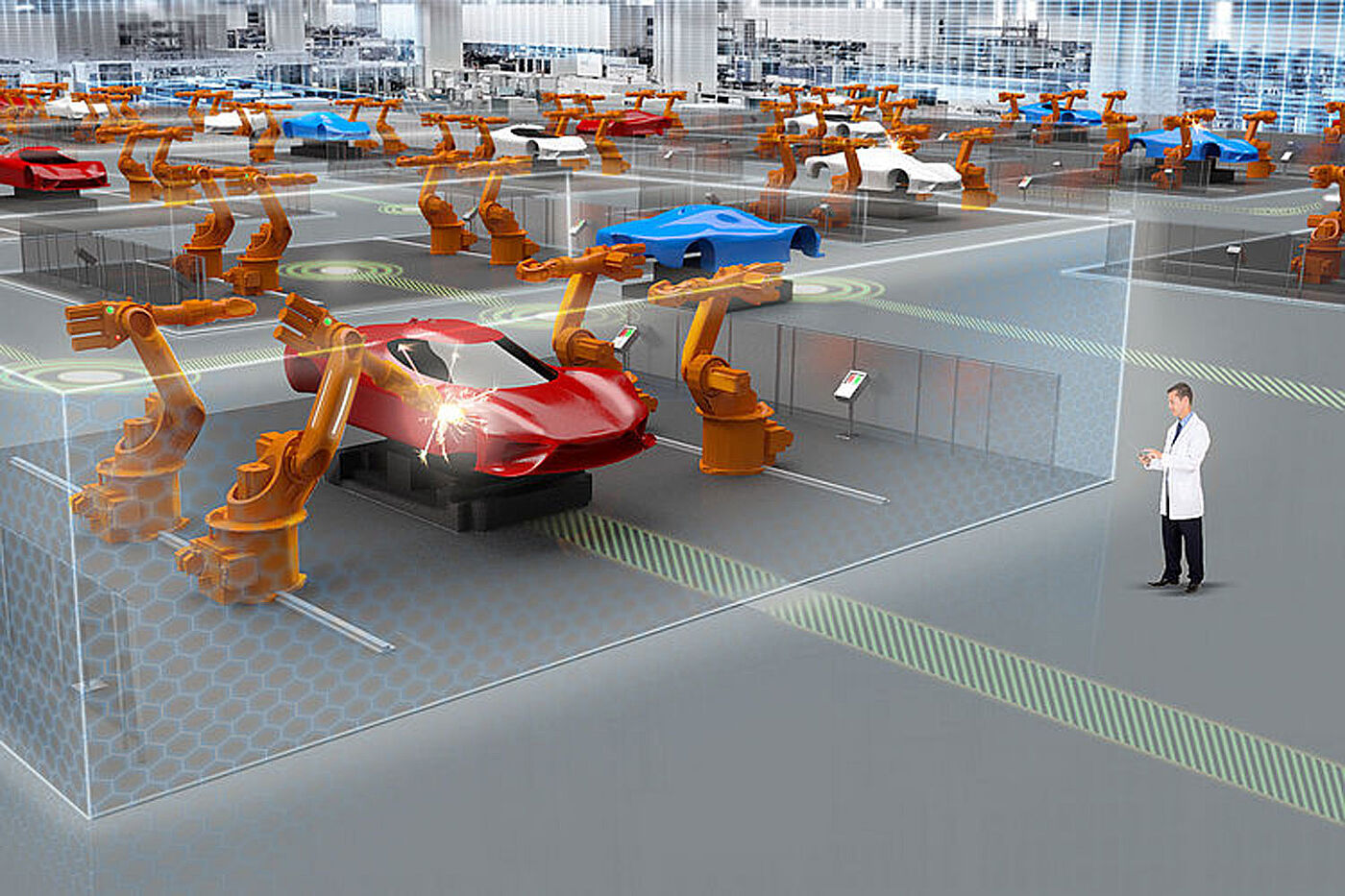

Automotive body construction

©

©

At Ingenics, the innovative planning of automotive body construction systems for car manufacturers and their suppliers involves far more than just meeting predefined requirements. That’s because, we plan your layouts not only for today’s needs – but also for tomorrow’s challenges. This includes wide ranging possibilities for the future integration of new car models within your existing production as well as planning for potential increases in overall production rates. This ensures the flexibility, as well as efficiency, of your automotive systems – today and far into the future.

Our goal is to help you realize long-term, sustainable automotive plants – with fully integrated factory planning, logistics planning, as well as automotive body production. And here, you can profit from Ingenics’ many years of planning experience in all major industries.

Ingenics project teams support this goal with: concept planning, the preparation of digital bidding documentation for turnkey facilities, simulations of production flows, detailed engineering and robot simulations. During project realization they also offer support from the initial in-factory preparation to the final achievement of your quality goals.

Increasingly, our consultants’ experience with advanced light-weight carbon composites is in high demand. Although these new materials will complicate some requirements in automotive body construction, carbon composite materials also offer significant advantages — due to their low weight and high strength, particularly in automated operations. Especially here, Ingenics consultants offer our customers tangible advantages, every day.

And as our customer, this means you can benefit from a wide range of synergies through a single Ingenics partner, who is always dedicated to your long-term success.

The future of the body shop: maximum flexibility and independence

Newly developed pit stop production as a core element of the solution

Central obstacles to making body shop construction systems more flexible and to increasing their transformation and integration ability are vehicle body assembly lines and the logistical supply of components. Ingenics has now succeeded in producing a layout describing the scenario of a future body shop that meets all foreseeable requirements. To this end, current restrictions and obstacles were analyzed before alternative solutions were worked out and turned into a coherent whole, known as “pit stop production.” This allows bodywork production that is independent from specific product requirements, ensuring maximum flexibility.

©

©