Operations Transformation: Successfully Becoming a Resilient, Future-Proof Organization

Why Is Holistic Operations Transformation Necessary?

In the manufacturing industry, there is growing pressure to change. Multiple political and economic crises, high regulatory requirements, and an increasing shortage of qualified workers all limit the possibilities for cost-effective action. The clock is ticking. Businesses in the manufacturing sector need to act now if they want to maintain their presence among global competitors.

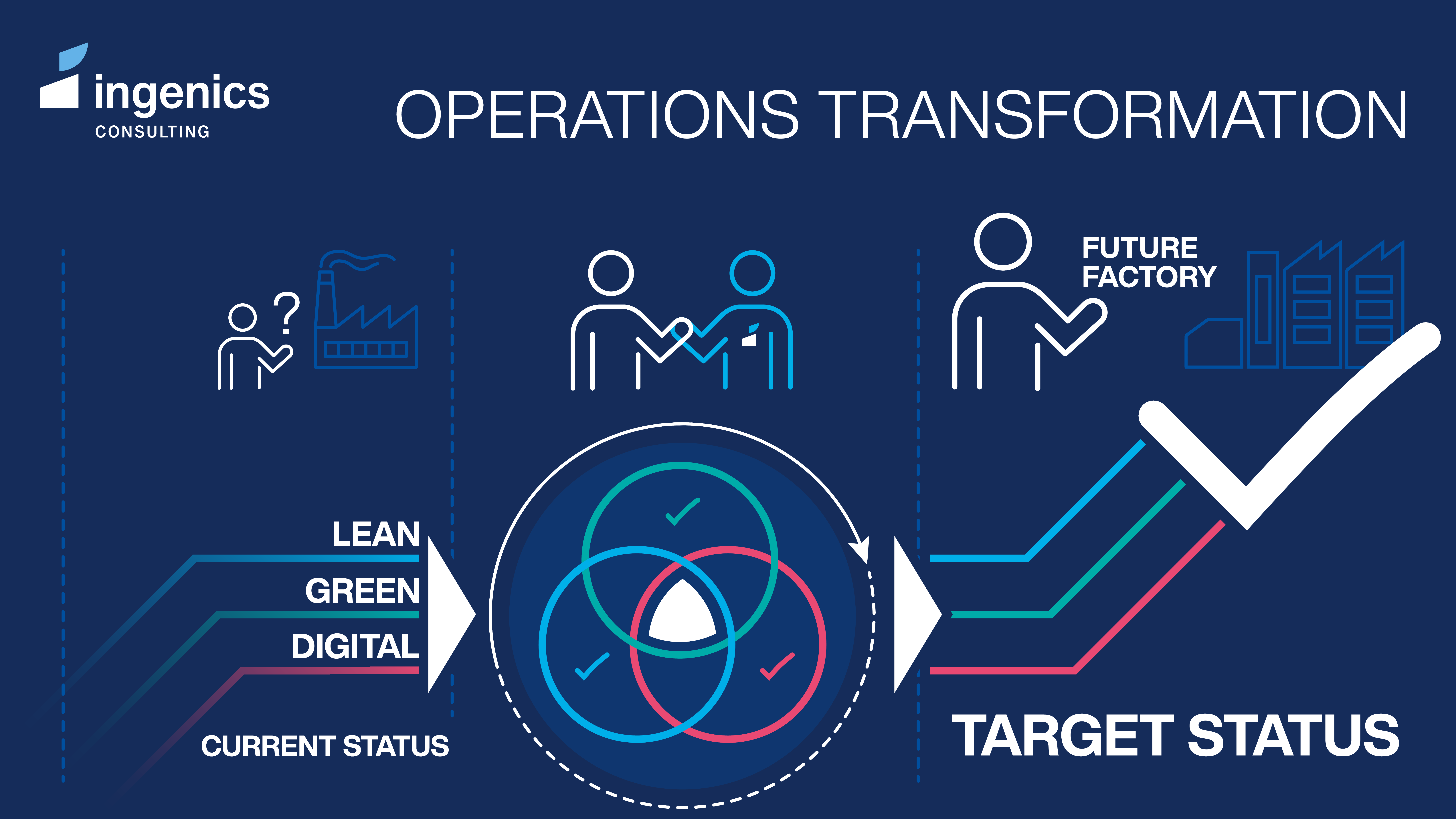

However, responding to these multidimensional risks requires a holistic approach. A single transformation process is not enough to strengthen a company against future threats. What's needed is a comprehensive operations transformation that harmonizes all business areas and prioritizes the full value chain and operational functions.

However, success can only be achieved when businesses strike a balance between the three core dimensions of holistic, functional, and continuous transformation:

By themselves, these approaches have limited effectiveness. A holistic view from an organizational development perspective is essential for them to unlock their full potential for increasing efficiency, lowering costs, and reducing complexity.

What Are the Core Challenges of Operations Transformation?

Manufacturing industries have always faced economic pressures to adapt. However, what’s new is the unfavorable environment surrounding this. The complexity of economic structures and the cost pressures are rising, while technologies are rapidly advancing and creating deep changes in the operational areas of production, logistics, and supply chains. To remain capable of effective action despite these challenges, a combination of transparency, flexibility, and sustainability is needed.

Most companies are keenly aware that they need to adapt to remain successful. However, the challenge lies in implementation. They may lack internal capacity, operational expertise, or a leadership culture that embraces change and excels in implementation. The largest challenge is integrating the three action areas of lean, green, and digital and embedding them permanently within the organization. The following questions should be asked:

- How can your business processes be digitalized and automated?

- What tools can you use to create a transparent data basis across all systems and departments?

- How do you increase your resource and energy efficiency to manufacture more sustainably?

- What can you do to create resilient supply chains?

- How do you establish an organization-wide continuous improvement process?

- What new vision of leadership is needed to internally guide this information (think New Leadership)?

- What measures are needed to embed this transformation among the employees through change management?

- Who are the right partners within the company for transformation management?

- How do you create effective strategies for implementing the measures?

Our experts are more than happy to help you identify the challenges that are hampering your operations transformation:

Three Action Areas at the Core of Holistic Operations Transformation:

1. Lean: Excellent, Flexible Production Systems

Cost-effective action is only possible when underpinned by efficient and robust processes. That is why the lean philosophy is and will remain the foundation of holistic operations transformation. Having said that, lean processes aren’t all it takes. It is essential to consider the human factor, as well. Businesses should initiate pragmatic efficiency programs that integrate the employees into a holistic, overall concept. Lean means more than just process optimization. It embodies a philosophy centered on value creation, questioning all activities that fail to add value for the customer. Businesses must embrace this philosophy to achieve holistic business transformation and ensure long-term security for their business models.

2. Green: Cost-Effective and Sustainable Success, Now and in the Future

Environmentally sustainable business practices are more relevant than ever, and not only because they’re socially responsible. There are economic aspects that are just as important for a green corporate strategy. Both Germany and the EU are adopting climate policies that increase the pressure on organizations to use sustainable practices. They have tangible financial consequences for companies, such as carbon pricing.

Consequently, a holistic transformation strategy needs to address aspects of environmental sustainability. Businesses should be quick to start optimizing the global footprint of their operations, fostering resource-friendly supply chains, utilizing renewable energy sources, and promoting a circular economy. Organizations that overlook these initiatives risk losing competitiveness in the future.

The path to a decarbonized zero-emissions company includes – though is not limited to – these areas of action:

3. Digital: More Transparency, Efficiency, and Autonomy

Holistic operations transformation goes beyond the scope of digital transformation. However, digital technologies are essential for the implementation of lean and green measures, making them an important enabler of the change process. They provide transparency and help manage the immense complexity of modern business structures and operational processes.

Digital technologies enable better management and data-based findings, raise the visibility of potential optimizations and integrate strategy, people, and processes in ways unimaginable in the analog world. These efficiency gains are a cornerstone of any holistic transformation strategy, which means targeted digitalization is indispensable.

Ingenics Is Your Partner for Operations Strategy and Transformation Management

Holistic operations transformation demands perseverance and a careful approach. However, it can generate lasting improvements with a small amount of resources. Thanks to our many years of experience in operations strategy and implementing optimization projects at the shop floor level, we’re able to turn strategic initiatives into measures that are ready to operationalize.

Operations Consulting: Strategy and Implementation Combined

When it comes to business transformation, we step in right at the point your company has made it to – with a comprehensive status quo analysis being the basis of our consulting service. We then employ a T-approach that integrates strategy and implementation. This approach includes not only defining an individual road map for the functional transformation of your value chains, but also prioritizing and putting in place individual measures connected to the three key drivers of “lean, green, and digital.”