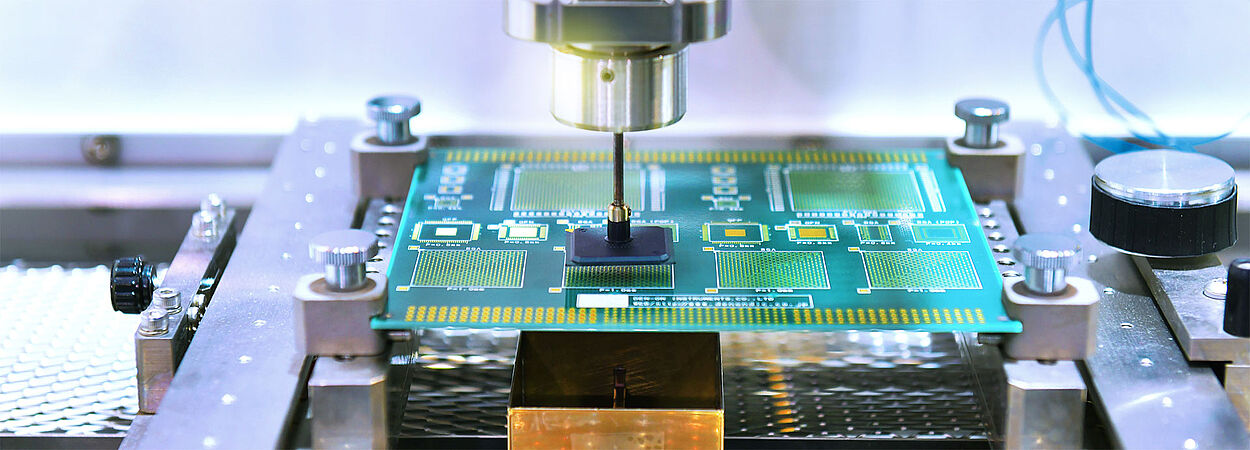

Electrical Industry: Responding Flexibly to Constant Change

There is hardly any other industry that is as driven by innovation as much as the electrical industry. Whether it be smartphones, computers, cars, or airplanes; almost all complex products feature their own electrical technology these days. The global demand for microelectromechanical systems (MEMS), circuit boards, and chips is constantly increasing. Electrical technology is now used in all aspects of life, from the smart factory to the smart home. This is why makers of electronic components need a high degree of adaptability. Both their production system as well as their products must be able to incorporate progress in automation, sensor technology, robotics, and sustainability in a flexible way. Concurrently, given the strong global competition, there is a growing focus on issues such as cost efficiency, operational excellence, and quality leadership.

What Will Be Important in the Electrical Industry of the Future?

To address future market demand, businesses in the electrical industry will need to invest in added capacity and new planning over the coming years. At the same time, they must successfully position themselves against competitors, especially in regard to rising customer demands for shorter delivery times and customization. This must be considered when designing an adaptable supply chain.

The future belongs to companies that make their business processes lean, efficient, and high-performing while integrating essential themes such as digitalization and sustainability. You can only achieve these goals when you develop the right solutions for your challenges:

- How can your company realize its planned growth successfully while maintaining its efficiency?

- How do you design a production environment to be modern and highly adaptable for future growth?

- How do you optimize your ability to deliver to customers and ensure material availability in a global network?

- How do you establish sustainable processes within the company and optimize energy costs in production?

Factors for Success in the Electrical-Technology Industry

Corporate Consulting for Electrical Technology

We Develop the Right Solutions with You

Our consultants have been supporting makers of electronic components with their challenges for years now. This is how we have concepts and standards which we quickly and effectively adapt to your situation and implement using professional project and change management. Using this expertise, our industry knowledge, and our growing international network, we can assist you in many fields:

Factory of the Future

How do you design production to be modern and highly adaptable for future developments?

Many manufacturers of electrical technology are on a growth trajectory. However, rapid growth frequently has a negative effect on efficiency. Constant capacity expansion and the unknown requirements for future products demand an ability to adapt production environments flexibly. Production in the electronics industry requires “built-in adaptability” for processes, structures, media planning, and layout design.

In an Industry 4.0 factory, areas such as logistics and production are efficiently interwoven. For this, you need to improve the material flow as well as the flow of information in processes themselves and in company divisions. Everything is predicated on well-thought-out factory planning, from the right site selection and ideal space requirements to the most appropriate working environments. Ingenics relies on building-information modeling (BIM) for this and consistently uses it as part of a holistic consulting approach from the outset and through all stages of the factory-planning process.

Manufacturing & Process Excellence

How do you reduce lead and cycle times to increase on-time delivery?

Short-notice orders in the electrical industry often result in a requested lead time that is shorter than the cycle time needed to fulfill the order. Lean management processes can optimize structures and shorten cycle times when combined with automation solutions. However, lean is more than just applying methods. What’s more, not every level of automation provides benefits for your production.

When implementing and enhancing the lean management philosophy, we do not just observe methods. Instead, we employ a holistic optimization approach. This helps you to shorten your cycle times, increase your output volumes, and improve the quality of your results. Our consultants use a human–robot collaboration (HRC) checklist to determine when and where investments in digitalization and automation solutions can pay off for you.

Production-Strategy Development

How do you harmonize the production strategy for products with high and low part diversity?

New products, custom products, and different requirements in different markets (laws, regulations, standards, etc.) result in a large diversity of parts in the electronics industry. In contrast, there is a large number of standardized and modular products with a very small diversity of parts. The challenge is to manufacture both product categories in the same factory and incorporate them into the production plan.

In such a volatile environment, businesses need to respond to change quickly and flexibly. We nurture this adaptability with an integrative, agile strategy approach. Based on a comprehensive observation of the value chain (through to the end user), we analyze the perspectives of all employees and managers. Building on this analysis, we work with you to define strategic action scenarios appropriate for the ongoing development of your digitalized organization. We derive initiatives from them and implement the initiatives with you without any productivity loss.

Resilient Supply Chains

How do you ensure material availability and delivery capability in global supply chains?

Political tensions, blocked trade routes, pandemics – singular events shake the global supply chains of the electronics industry time and again. Resilient supply chains and well-structured supplier management are, therefore, indispensable for long-term competitiveness.

The economic planning and optimization of supply processes, to include lean management principles, is the focus of our supply chain management approach. This knowledge is of particular importance for assessing the effects of a strategic realignment. Our focus is on a proven methodical approach, which we can quickly adapt to your situation.

Logistics Optimization

How can you reduce logistics costs – while maintaining quality?

In the electrical industry, many materials are highly sensitive and costly. Therefore, particularly high demands on logistics and material handling apply here. Additionally, logistics is subject to competitive cost pressures. Inefficient logistics processes, which have long been accepted due to high profit margins, are accordingly no longer acceptable.

At many manufacturers, there is still significant potential for improvement in logistics, for example in terms of transparency, flexibility and speed. We use a detailed value stream analysis of your product to determine the areas in which improvements can be made. Based on this, we work with you to develop and implement a future-proof logistics concept that takes all quality requirements into account.

Ingenics Consulting Testimonials in the Electrical Industry

Potential Analysis for a German Electronics Service Provider

• Identifying areas for action to optimize electronics manufacturing for circuit-board placement (SMD and THT), applying operational-excellence criteria

• Discovering potential for segmenting product categories and line assignment for harmonizing production management and cost optimization

Logistics Concept for Supplying Production with Semiconduc-tor Manufacturing Optics for a Leading German High-Tech Company

• Finding areas for action for optimizing material flow in production supply

• Developing a target vision for standardized supply of sets, for replenishment management with kanban, and for optimization by concentrating supplier scopes

• Defining detail for the logistics and provision concepts on the production lines (handling and provision spaces) and technical specifications for the equipment required

Factory Concept for a Manufacturer of Sensors for Industrial and Automotive Applications

• Increasing productivity by 30 percent with holistic factory planning, automation, and logistics with digitalization approaches

• Conceiving a line-based manufacturing layout, including defining technical details for a 1,200 sqmeters clean room

• Evaluating the use of new manufacturing and automation technologies and developing concepts that incorporate the use of CAPEX/OPEX methods

• Defining a logistics concept for supplying and disposing of material for front and back ends and space-optimized warehouse design

Optimizing a Production Line for Repairing Management Systems at a Leading Aviation Manufacturer

• Analyzing the value stream, recording time components in current production, and finding optimization for process times, cycle times, and buffers

• Developing a TARGET process (with a PERT chart) for harmonizing workstations, machines, and material-replenishment concepts for the machines

• Creating and adjusting the needs calculations for employees, equipment, and machinery

• Overseeing the implementation of changes in existing manufacturing areas