Securing future sustainability of your company within the supply chain

The automobile industry, and automotive suppliers in particular, are faced with fundamental shifts, both within the sector and in the markets.

These require that existing business segments and products be stabilized as well as secured. And even more significant, fundamental shifts in the mobility sector are placing a high level of pressure on these companies.

©

©

Ingenics supports its customers in answering the following questions:

- How can a supplier secure and enhance its own position within the supply chain?

- Which opportunities exist for the companies to achieve complete fulfillment regarding deadlines, promises of delivery, and their contractual obligations?

- Which measures do decision-makers implement in order to achieve the necessary transparency regarding their own company, the KPIs, and the supply chain?

- How should the supplier deal with the catchword “digitalization”? Which path should the company take in order to exploit digitalization potentials in a sustainable manner unique to the company in question?

Based on decades-long intensive support to the automobile industry, Ingenics sees four main fields of activity for the companies:

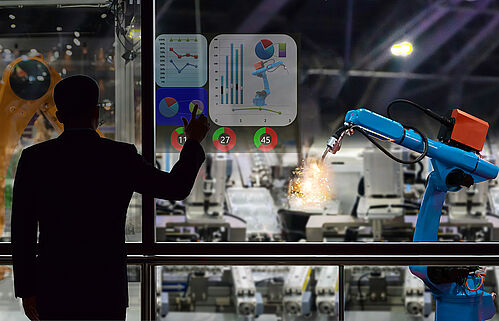

Utilizing potentials for digitalization

©

©

For many people, digitalization has become a catchword which is used in an inflationary manner. But what does it really mean? What would the right path for a supply company in the automotive sector look like in order to truly benefit from digitalization?

Here as well, Ingenics applies its approach tailored to the individual customer which begins by taking an inventory of processes and IT systems. In every case the perspective taken and with it the master plan developed will always embrace the entire company, all its departments and their interfaces, both company-internal and with the supply chain/customer.

However, the recommendation and method are always based on the priorities established as a team, so that changes can be made successfully and in parallel with the challenges of daily business. This also means that the employees, some of whom hold a critical stance towards this catchword, become part of the initiative. During the projects efforts are made to convince the participants, who are also informed and qualified by means of appropriate training.

For suppliers, utilizing digital potential means the intelligent networking of all players in the automotive supply chain to make processes more transparent.

This is facilitated through the availability of relevant data in real time. Under the key words Assembly/Production 4.0 (networking data and information structures of previously separate areas) and the Internet of Things (IoT – linking and networking – via an IoT platform – devices and machines which previously worked and obtained information independently) the company opens up significant potentials for improving information, communication, and decision making.

As a result the company achieves a highly agile process structure and a supply chain that provides information in real time. These can also be adapted quickly using specific triggers. This flexibility and rapid reaction capability are based on IT systems integrated both vertically and horizontally.

You can find further information under the heading “Digital Transformation and Industry 4.0”.

Creating transparency

©

©

The more complex the structure of the automotive supply chain, the more multifaceted the interdependencies with subsuppliers and the more finely meshed the process structure, the more important the topic of transparency becomes for the automotive supplier.

And applies not only to the “tier 1” suppliers, but also for subsequent levels. At this point there would likely be a knee jerk reaction to interject the catchword “digitalization”. Yes, digitalization plays a major role here – detailed information on this is provided under the fourth field of activity. But before things can be digitalized it must first be established how transparency can be created in the first place.

On the topic of transparency focus should be placed both inside the company itself and its production processes, but equally in the supply chain and the subsuppliers involved in it. The goal must be to develop a business intelligence solution for the individual company by applying a sufficiently efficient IT support system. To meet this need Ingenics has developed its own business intelligence solutions which are adapted to individual customers – the “Ingenics Cockpits”.

- “Ingenics Production Cockpit 4.0” with a focus on the supplier’s own production range

- “Ingenics Intralogistics Cockpit 4.0” with a focus on logistics processes on the company’s own premises and the option of including subsuppliers

The Cockpits provide the relevant information tailored for use. They are based on the sector-specific, broad scope of experience of the Ingenics teams.

The Ingenics Cockpits are the only ones on the market that combine classic IT expertise (key words: business intelligence and digitalization) with extensive competence on the shop floor, in process optimization, and the lean approach.

You can fiind further information here on “Ingenics Production Cockpit 4.0” and “Ingenics Intralogistics Cockpit 4.0”.

Stabilizing processes within the supply chain

©

©

The more complex the supplier structure and the more multifaceted its interdependencies, the more challenging it is for the automotive supplier to keep its business processes stable across the supply chain. It often requires a great deal of effort for original equipment manufacturers (OEMs) to achieve complete fulfillment regarding deadlines, promises of delivery, and their contractual obligations.

Analysis of these fields of activity points up the status of supplier-based processes and the potentials they contain; these can then be developed by means of the following standardized methods:

- optimization of the organizational structure

- optimization of project management

- optimization of business and work processes (business process management – BPM)

- optimization of order management

- optimization and harmonization of production systems

- application and introduction of lean methods (Five Whys method, CI process, etc.)

These methods aim at sustainable and stable improvement in process quality and the introduction and application of the CIP (continual improvement process) method. In parallel, the processes are evaluated in terms of current IT support and suggestions are developed in line with the motto “IT follows process”; these are then put into practice with the company.

If necessity and willingness allow, such optimization is implemented cross-company – in other words it includes the automotive subsuppliers themselves. In this way Ingenics is able to ensure that appropriate structures and processes are created on the subsupplier side to fulfill the requirements of the upstream company.

As a result, the company is in possession of stable processes along the entire supply chain, works with high efficiency, and significantly reduces manual efforts. This optimizes collaboration with the subsupplier, and the harmonization thus created enhances the attractiveness of the upstream company as contracting entity.

You can find more information on this in the service module “Process and Organizational Consulting”.

Optimizing supplier management

©

©

Acute crisis or sustainable optimization? Where is there need at present? In both cases Ingenics can help!

In the case of an acute crisis with a subsupplier, rapid intervention is the first priority. The Ingenics approach is to assemble an interdisciplinary team which promptly acts to analyze the crisis, derive intervention measures, and provide support during implementation. In this way the precarious situation is alleviated in the shortest possible time, thus averting further or more serious consequences. However, the topics established during intervention should then be utilized in performing a rigorous investigation of the supplier management system.

As a rule, such a crisis results from the escalation of the fundamental problems of a subsupplier or the supplier management system itself – in other words it represents a fundamental issue. It involves long-term collaboration with and management of suppliers across the entire life cycle of the cooperation in the automotive sector.

Ingenics provides ongoing support to its automotive customers during the process of creating and professionalizing a supplier management system. This support focuses on the following objectives:

- to ensure cost efficiency and supplier reliability

- to define and ensure the quality of supply

- to optimize procurement costs

- to effectively and efficiently manage suppliers

- to collaboratively optimize cross-company processes

- to sustainably minimize supply risk

- to establish and expand strategic cooperation with important suppliers

This yields a management system which is based on concepts and key performance indicators and at all times can provide a detailed overview of the company’s own subsuppliers, their current performance and their development status.

You can find further information here on the service module “Supplier Management”.

“First come the quick wins, then the long-range perspective” – the customer case study on transparency, process risks, and efficiency in the intralogistics of the automotive supplier König Metall GmbH & Co. KG

“A new solution had to be found, in particular for parts which are only handled and stored at the main plant; but we want to maintain direct control over actual production logistics in the future. However, as suggested by Ingenics, this is an area that has to be optimized with a transport control system and a direct connection to the ERP system.”

Hans-Jörg Leuze, managing director at König Metall GmbH & Co. KG

Ingenics is a competent partner of the automotive supply industry which takes a collaborative approach to the above fields of activity hand-in-hand with its customers.

The consultants at Ingenics have extensive industry experience and a wide knowledge of methods, all of which allows them to tailor their services to suit the demands of individual client projects.